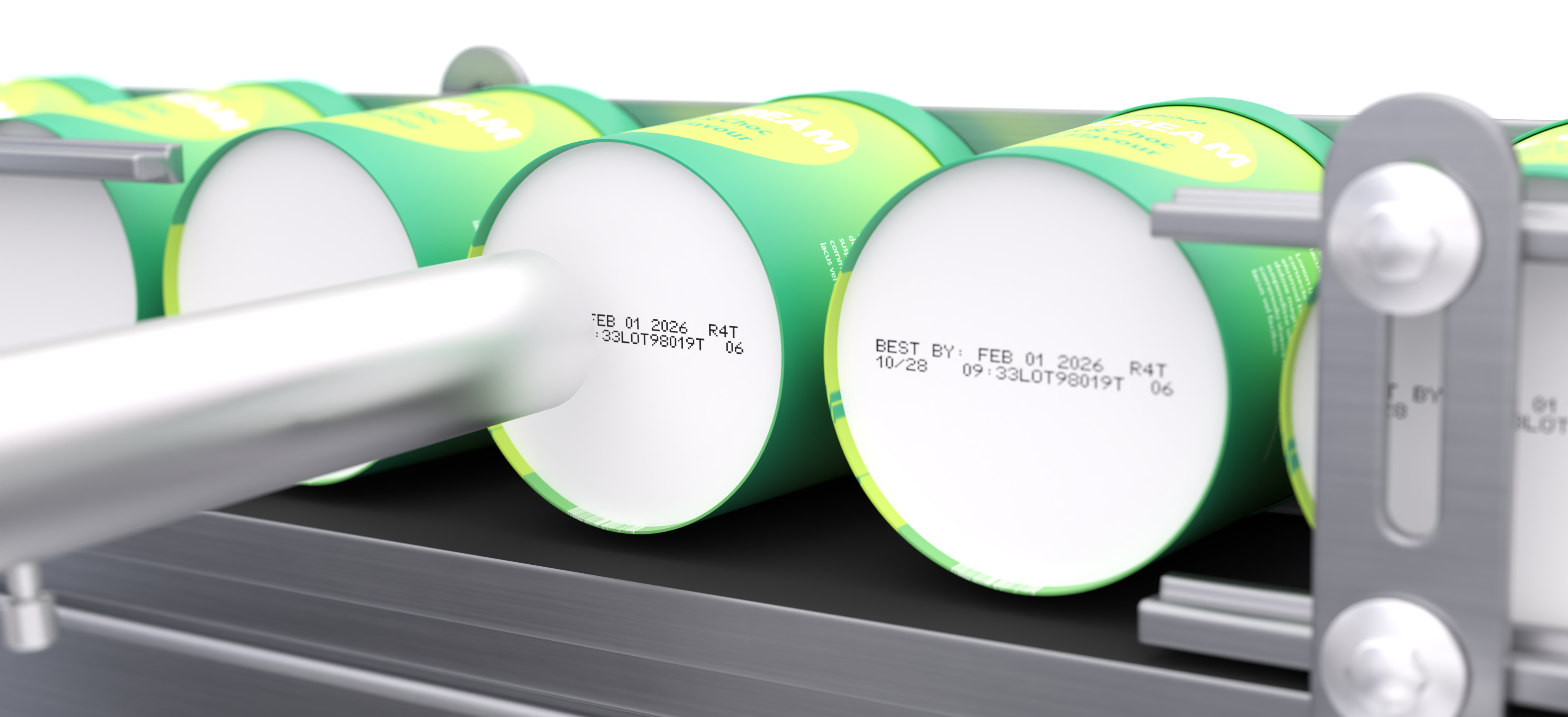

Well-crafted codes help the dairy industry meet strict standards and minimize errors in fast-paced production environments

In the dairy industry, every printed detail counts. A single misprinted date code can lead to costly product recalls, regulatory penalties, or a loss of consumer trust. That’s why accurate, high-quality on-package printing—such as date and lot codes—is critical for dairy products. These variable codes are essential for ensuring traceability, meeting regulatory standards, and providing consumers with vital product information.

However, dairy packagers face a major challenge: achieving durable, high-quality coding under tough conditions while keeping the packaging process efficient. To achieve the best possible code quality and accuracy, several factors must be carefully controlled:

- Selecting the optimal printer for each application.

- Managing the data to be printed, keeping it accurate and reducing the risk of errors.

- Using text and barcode inspection systems to verify that each printed code meets the required quality standards.

- Minimizing unplanned downtime.

Choosing the right print technology for dairy packaging

In the fast-paced world of dairy packaging, selecting the ideal printing technology is essential to maintaining product traceability, regulatory compliance, and brand quality. Here’s a closer look at the top solutions available today.

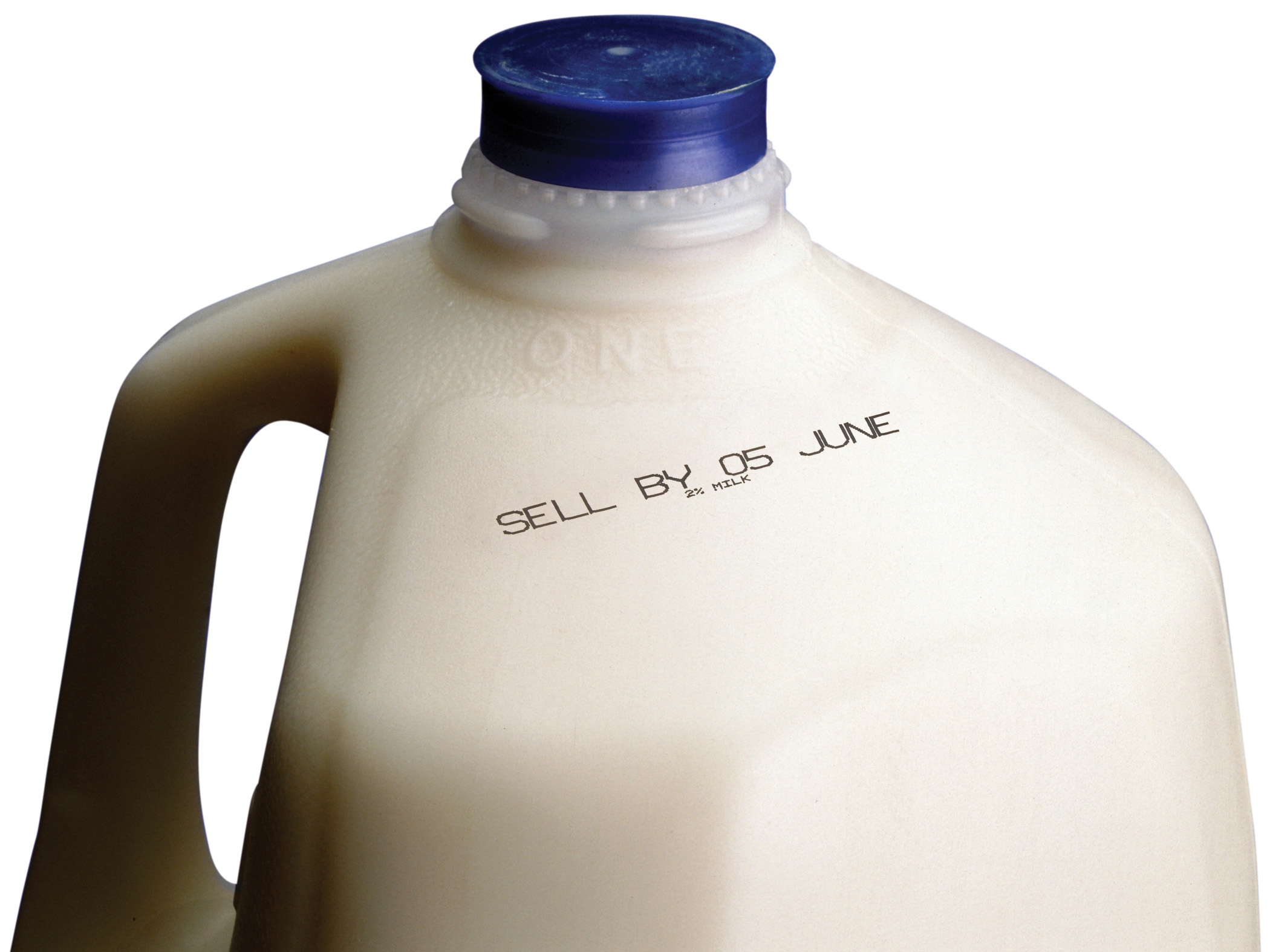

Continuous inkjet (CIJ) printing technology is well known for its ability to print on a wide range of packaging formats used in the dairy industry, including milk jugs, metal cans, Tetra Paks, glass, and many types of plastics.

- A low cost per print makes CIJ cost-effective for high-volume production. With available IP65 and IP66 environmental protection, the printers can be used in the harsh conditions encountered in dairy packaging plants.

With a high print resolution—up to 600 dpi—and minimal maintenance requirements, thermal inkjet (TIJ) printers can print high-resolution messages including text, barcodes, and 2D codes, onto a wide range of packaging materials, including cartons and flexible packaging.

- TIJ printers are capable of printing high-quality 2D codes, making them a good solution for brands adopting GS1 2D codes for Sunrise 2027.

Thermal transfer overprinters (TTO) are an excellent solution for adding variable information to flexible packaging, such as bags, pouches, and labels.

- The Videojet 6530 TTO (53mm version) and 6330 printers feature Videojet iAssure™ technology – a built-in system for detecting defects in printed codes.

- With print widths of 32mm, 54mm and 107mm, Videojet TTO printers can handle a wide range of applications from simple date and lot coding to the printing of linear and GS1 2D codes, ingredients lists, and other product information.

Laser marking systems create high-quality images on various materials without the need for inks or chemicals.

- They are available with several different light wavelengths, ranging from infrared (CO2 lasers) to ultraviolet (UV lasers), as well as various power outputs. This allows for the ideal laser to be matched to nearly any application.

- Videojet lasers can be supplied to IP54 and IP69 environmental standards to operate in harsh conditions.

Large character inkjet printing

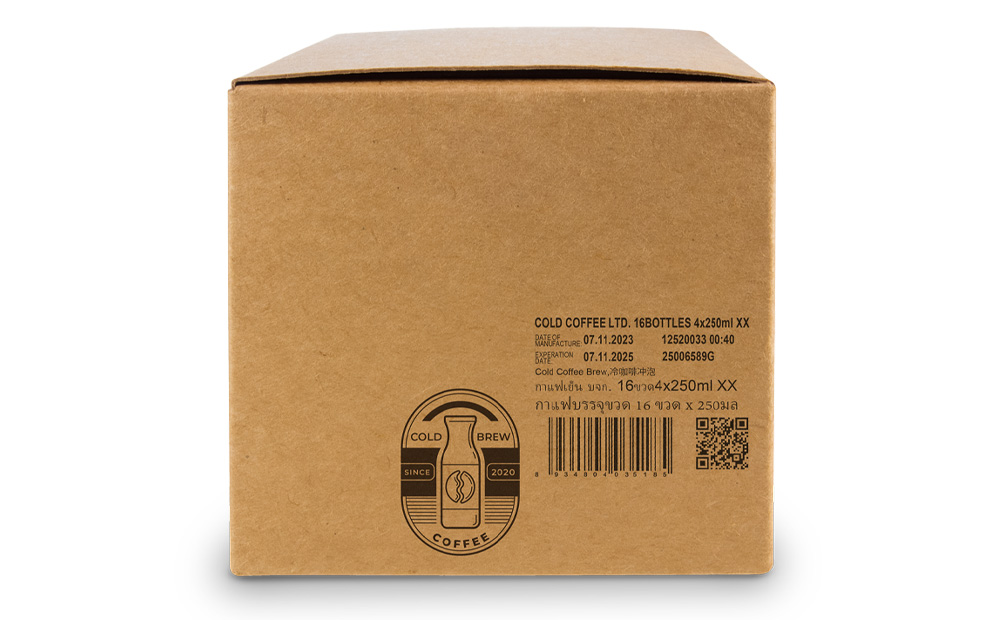

Large character markers (LCM) can print text, logos, and barcodes directly on secondary packaging, such as shipping cases.

- With a self-cleaning printhead, the Videojet 2380 can print up to 70mm high per head and up to 4 x 70mm for a system. A single touch-screen controller can manage up to four printheads.

- Ethernet and Wi-Fi connectivity allows for integration into your production systems.

The Videojet 9560 print and apply labeler handles the demands of modern high-speed packaging lines, printing and applying labels to cases, boxes, and shrink-wrapped trays.

- Videojet Direct Apply™ technology eliminates common causes of label jams and downtime, maximizing the efficiency of your secondary packaging labeling operations.

The Videojet 9560 PL pallet labeler is engineered to print and apply up to four labels to each pallet at speeds up to 120 pallets per hour.

- Uptime is maximized with Videojet Intelligent Motion™ technology, eliminating the need for daily adjustments.

- Its intuitive design features the industry’s simplest web path, enabling quick and hassle-free label and ribbon replenishment.

Discover coding solutions for every dairy package

From flexible films to rigid containers, modern coding technologies produce high-quality codes on diverse packaging materials. Find the ideal solution for your packaging needs:

| CIJ | Laser | TTO | TIJ | Print & Apply | LCM | |

| Hard plastic |  |  |  | |||

| Paperboard and laminated paper |  |  |  | |||

| Flexible film |  |  |  |  | ||

| Glass |  |  |  | |||

| Metal |  |  | ||||

| Secondary packaging |  |  | ||||

| Tertiary packaging |  |

Managing code data

After selecting the optimal printer for your specific situation, it’s essential to have control over the data so that it’s always accurate for the current production run.

Videojet CLARiSUITE® Code Assurance Solutions are fully integrated to link on-product coding to a centralized message database. When the Videojet printers in your facility are managed from a central database, there is no need for production line personnel to manually enter or change print messages.

Integrating with your coding systems, Videojet CLARiSUITE also manages your label templates and printing for your secondary and tertiary packaging (including Videojet, Zebra, and SATO printers), giving you control over all the coding, marking and print/apply data on your packaging line.

Code quality can’t be an afterthought

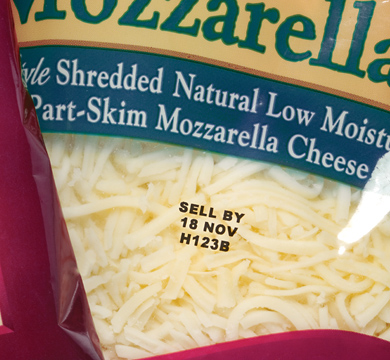

There is no room for error. Making sure printed codes on packaging are accurate and meet quality standards is essential for dairy packagers. Variable information on each package must comply with regulatory requirements, like those set by the U.S. Food and Drug Association and similar organizations, while remaining easy to read for both retailers and consumers.

With GS1 2D codes becoming part of the online coding process, an additional level of quality control is needed to be certain that your printed 2D codes meet or exceed the minimum quality levels.

Videojet CLARiSUITE® can help address these quality control needs – the system supports both fixed-mount barcode scanners (connected to a printer or networked) and integrated, vision-based print inspection systems, that can perform quality inspection on barcodes.

Online vision solutions from Videojet can handle several important tasks, including:

- Barcode scanning and validation: check that each barcode scans and contains the correct information

- Verify that GS1 barcodes meet the standard for print quality

- Check for the presence of printed codes, such as date and lot number

- Carry out OCR/OCV inspection on printed text – confirm that the data is correct, and it meets the acceptable quality level

Monitoring print quality improves efficiency by immediately catching any problems, eliminating the downtime caused by rework.

What if your printer could tell you exactly what it needs? With VideojetConnect™ Remote Service, it can. This cloud-based system monitors your printers in real time, tracking fluid and ribbon levels, detecting errors, and sending alerts when action is required—all to help reduce unplanned downtime. You can remotely access your printer’s operating system to troubleshoot, adjust settings, and even back up or transfer configurations with ease. Expert support is also available remotely, reducing the need for on-site service visits.

Final thoughts

Accurate, high-quality codes are crucial for dairy producers, and the systems used must be able to operate at peak efficiency in the cold and damp conditions often encountered in the dairy industry.

Ready to protect your dairy brand with codes you can count on? By partnering with Videojet, you gain access to a full suite of advanced coding solutions—including CIJ, TIJ, Laser, and TTO printers—along with powerful software for efficient printing and seamless data management. With the added benefit of remote monitoring to reduce downtime, Videojet is here to help you streamline operations and achieve your production and efficiency goals with confidence.

Additional reading

Videojet: Dairy coding and marking solutions

Videojet: Cognex vision systems

Videojet: Videojet-Laetus vision systems

Stay ahead with real-time updates on the latest news: