High-Performance Thermal Inkjet Printers (TIJ) for Industrial Applications

Videojet’s Thermal Inkjet Printers (TIJ) offer a full range of high-resolution printing solutions for text, barcodes, and graphics. Designed with cutting-edge TIJ technology, these printers are ideal for applications where precision and ease of use are critical. Maintenance is hassle-free, requiring just a simple wipe of the cartridge print array and printhead, making these printers the perfect choice for fast, efficient, and reliable printing.

Why Choose Thermal Inkjet Printers?

From basic alphanumeric codes to complex barcodes and graphics, Videojet thermal inkjet printers are engineered to enhance productivity, quality, and efficiency. Key features include:

- Portable Ink Level Tracking: Provides real-time visibility to avoid production interruptions.

- Automatic Cartridge Setup: Eliminates user error and simplifies operation.

- Advanced Data Handling: Ensures accurate and flexible code generation.

Videojet TIJ printers

Thermal inkjet (TIJ)

Videojet 8520/Wolke m610 touch

Thermal inkjet (TIJ)

Wolke m610 advanced

Thermal inkjet (TIJ)

Wolke m610 oem

Applications

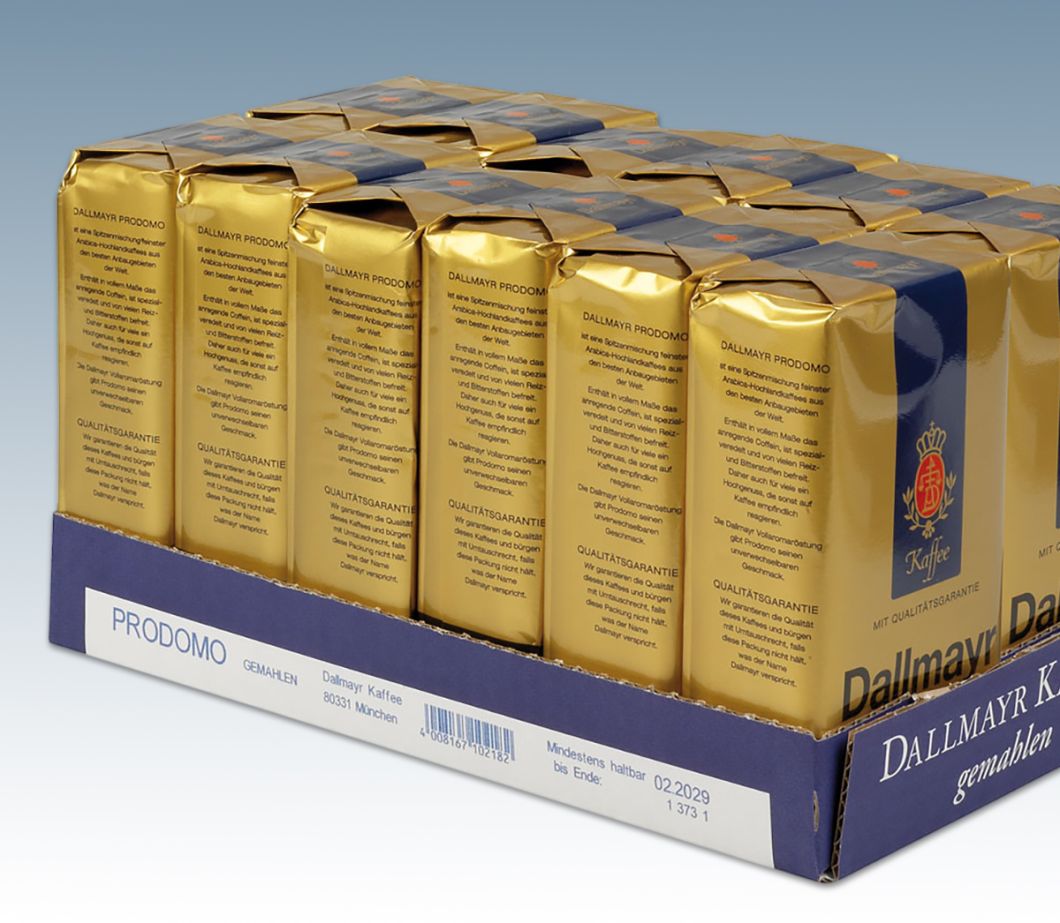

Versatile thermal inkjet printers are used across various industries for coding and marking applications. They excel at printing high-resolution barcodes, expiration dates, batch numbers, and promotional graphics directly onto packaging, labels, and products. Commonly employed in food and beverage, pharmaceuticals, cosmetics, and electronics, their ability to adapt to different substrates and enable quick changeovers make them ideal for dynamic production environments, streamlining operations and improving efficiency.

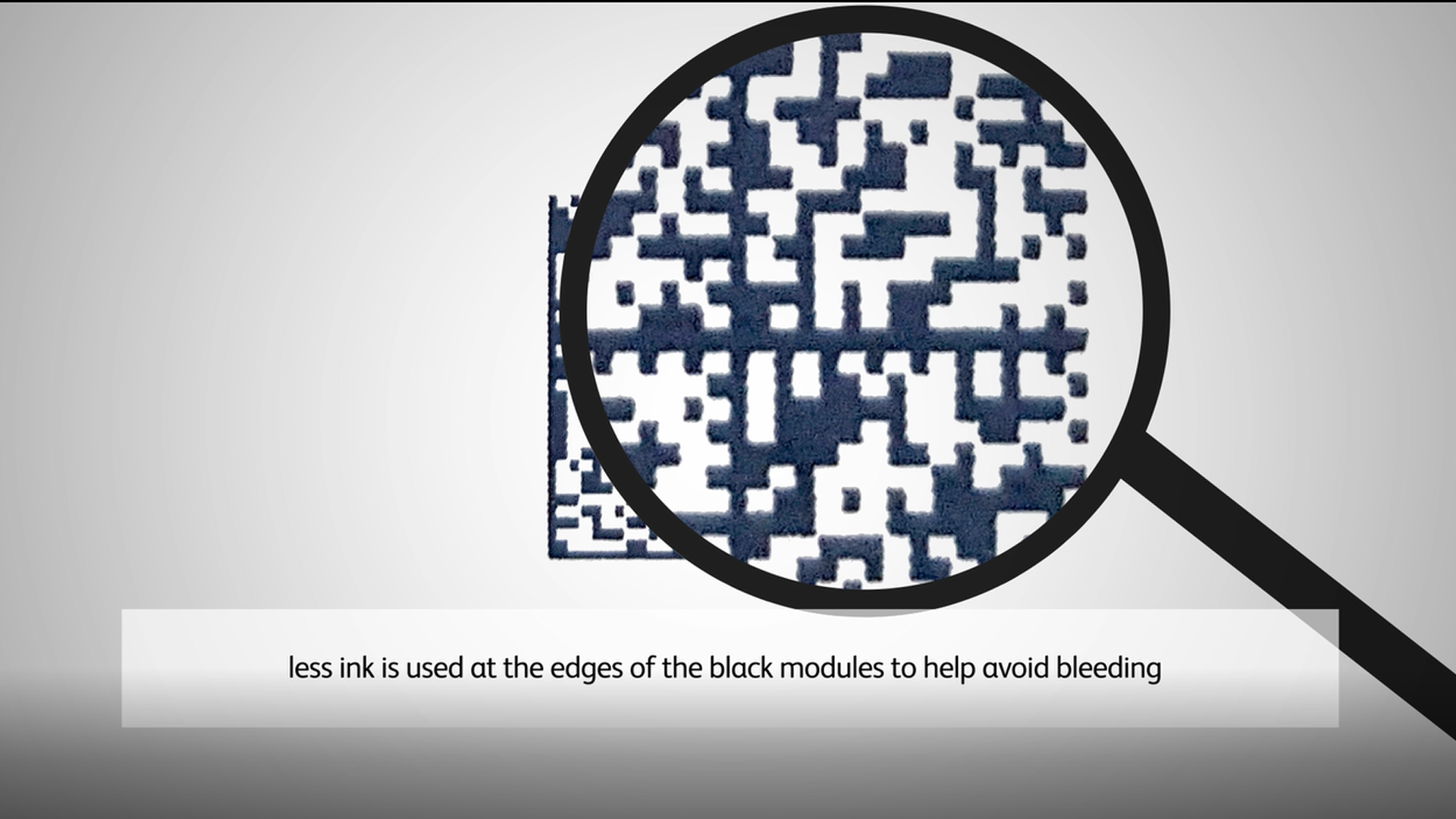

Thermal Inkjet Printers (TIJ) are high-resolution printing devices that use heat to create sharp, precise prints on various surfaces. They are ideal for printing text, barcodes, graphics, and traceability codes with minimal maintenance and user-friendly operation.

TIJ printers are widely used in industries like food and beverage, pharmaceuticals, electronics, and medical device packaging. Their ability to produce clean, high-resolution prints makes them essential for product labeling, traceability, and branding.

TIJ printers offer several key benefits:

High-resolution prints for clear and professional results.

Low maintenance with easy cartridge replacement and cleaning.

Compact and user-friendly design suitable for various production environments.

Cost-effective operation with no need for bulky consumables.

Videojet and Wolke TIJ printers are designed for reliability and ease of use. Key features include:

Automatic cartridge setup to reduce errors.

Advanced data handling for complex codes.

Clean, no-mess operation with solid-state electronics.

Wolke printers, specifically, excel in high-resolution coding for pharmaceutical and medical packaging.

Yes, TIJ printers like the Videojet 8520 are specifically designed for high-speed production environments. They offer seamless integration, scalable print height options, and precise coding to ensure efficiency and reliability in fast-moving operations.