Melissa Bosnyak

June 2025

I recently had the privilege of attending the Sustainable Packaging Coalition (SPC) Impact event in Seattle, WA. Over 700 attendees representing the packaging industry, government, and academia came together to explore this year’s theme: Harmonizing Action. The event stood out not just because of its scale but also because it welcomed both SPC members and non-members, creating a unique space for collaboration.

As I left the conference, I couldn’t help but feel inspired by the collective drive to improve packaging sustainability. Even with federal deregulation and uncertainty looming, the industry’s commitment to circularity felt stronger than ever. The event was sold out, and the energy in the rooms reflected a shared determination to tackle the challenges ahead. For me, the diversity of participants—from raw material suppliers to material recovery facility operators—was a powerful reminder of how interconnected the packaging value chain truly is.

A new appreciation for packaging

Before attending SPC Impact, I was already well aware of the complexities involved in packaging. However, this event deepened my respect for the intricate processes and partnerships that make packaging innovation possible. Listening to companies like Unilever discuss their shift from HDPE to PET with shrink sleeves or Amazon unveil direct-fill packaging that reduces waste reminded me how dynamic and collaborative the industry can be.

Packaging might be an afterthought for consumers, but designing it requires a delicate balance of sustainability, functionality, and innovation. The conversations at SPC Impact made it clear how essential it is to harmonize efforts across the value chain to create solutions that are not only effective but scalable.

Key themes that stood out

Several themes emerged from the sessions and discussions. Here’s what resonated with me the most:

- Extended Producer Responsibility (EPR) isn’t coming—It’s already here

- We’re at the tipping point for climate action

- Sustainability is a journey, not a destination

Stay ahead with real-time updates on the latest news:

EPR: The time to act is now

For years, EPR felt like a distant possibility in the U.S., but that’s no longer the case. Since Maine and Oregon passed the first EPR laws in 2021, the reality of EPR has started to set in. We have even surpassed the first deadline with Oregon. March 31, 2025, was the deadline for producers to register with the Circular Action Alliance (CAA), and it has left many companies scrambling to gather essential data such as material composition, sales volumes, and more.

It was clear from the discussions that even large, well-resourced brands are facing challenges.

Hearing from international speakers who have navigated EPR in Canada and Europe was invaluable. Their insights highlighted the importance of gathering accurate data and learning how to manage multiple schemes effectively. These lessons can help companies avoid some of the growing pains experienced by others.

A few companies are choosing to wait it out, not buying in to their obligations. As Jeff Fielkow, CEO of CAA, emphasized, waiting to act only increases costs and risks for organizations. Delaying compliance could result in retroactive fees and higher expenses. If a company with obligations wants to better understand the EPR landscape, I’d highly recommend looking into the SPC EPR Policy Collaborative. This cross-industry group offers invaluable resources for staying informed and preparing for these changes.

The tipping point: Take action or be left behind

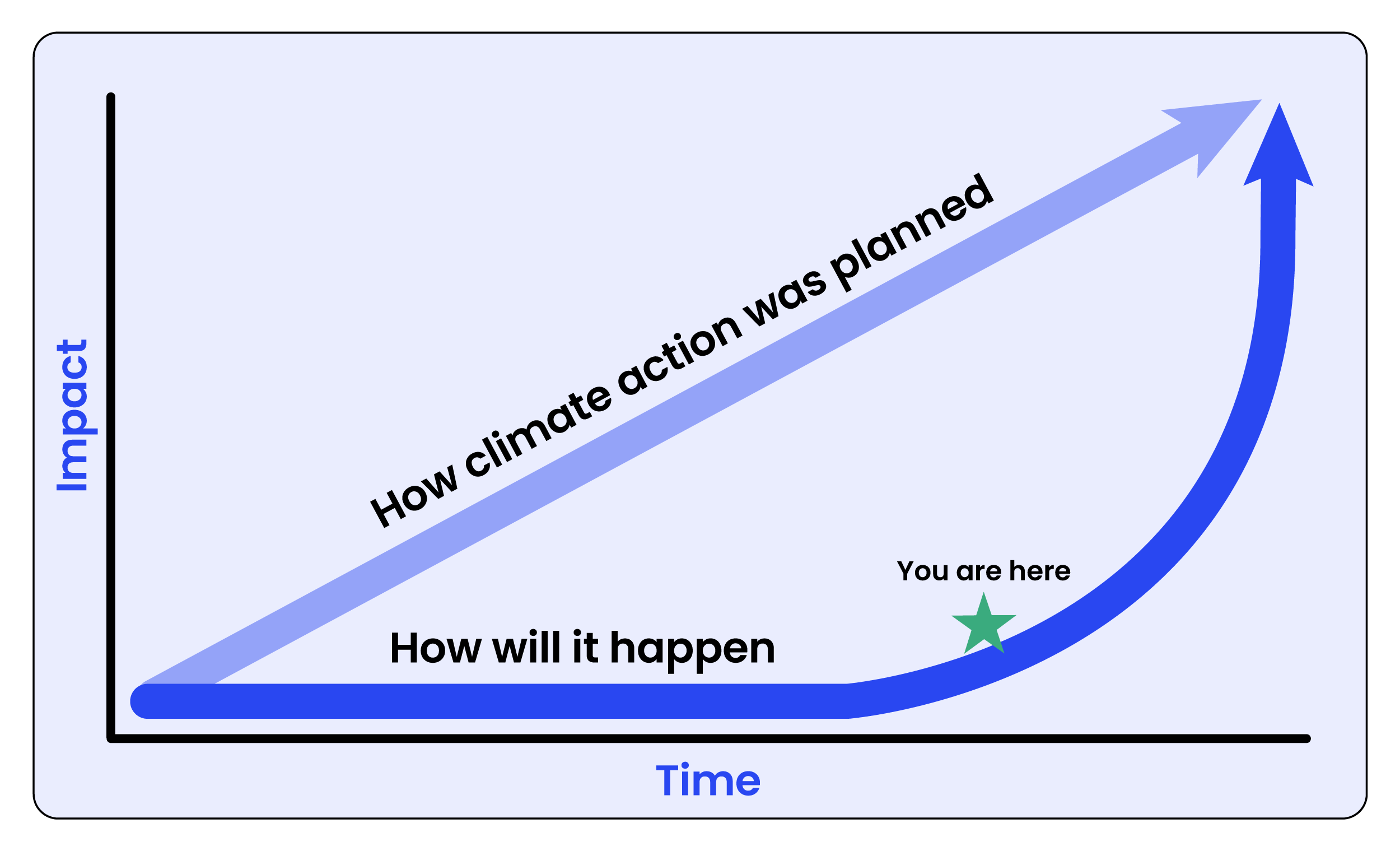

Keynote speaker Solitaire Townsend, co-founder of Futerra, delivered a powerful message about the state of climate action. She presented an image, much like the one to the right, to illustrate the difference between how we expected climate action to happen, and how it is happening. We see how progress over the past few decades has been slow and gradual at first, but in the more recent years, we’ve seen acceleration. Her message was clear: we are at that critical moment now. With exponential advancements in technology and innovation transforming the packaging industry, companies that don’t adapt quickly risk being left behind.

Paul Nowak, Executive Director of GreenBlue, reinforced this sentiment, reminding us that this generation expects more from us. He urged attendees to challenge themselves by engaging in spaces they wouldn’t normally operate in. This call to action hit home for me—it’s not enough to maintain the status quo; we must push boundaries and innovate to stay relevant and make an impact.

Sustainability: A journey, not a destination

One of the biggest takeaways from SPC Impact was the reminder that sustainable packaging is an ongoing journey. There’s no one-size-fits-all solution, and the industry will never have a singular “end point.” While this complexity can be daunting, it also creates space for collaboration, innovation, and continuous improvement.

Take, for example, the shift from Styrofoam coffee cups to paper-based alternatives a decade ago. At the time, it was a significant step forward for sustainability. But today, some paper-based cups pose challenges for recyclability, pushing the industry to rethink solutions. The lesson here is that what worked yesterday might not meet tomorrow’s standards—and that’s okay. Sustainable packaging will always evolve as technology, consumer behavior, and recycling infrastructure advance.

Starbucks exemplifies this iterative approach. Amelia Landers, VP of Product Experience Innovation at Starbucks, shared how their team focuses on “doing the next right thing.” One example was providing reusable cups to employees after discovering that 10% of their daily packaging volume came from internal use. It’s a simple yet impactful step that aligns with their broader sustainability goals. As Amelia said, “There’s no IP for sustainability at Starbucks.” Their wins are shared wins for the industry, embodying the spirit of harmonizing action.

Marking and coding: A critical piece of the puzzle

As someone deeply involved in marking and coding, I appreciated the opportunity to discuss its role in sustainable packaging. While marking and coding might not always be top of mind during packaging transitions, it plays a critical role in ensuring compliance, traceability, and functionality.

When brands shift to new materials, they may face challenges in maintaining the same level of performance from their marking and coding solutions. For example, paper-based films often interact differently with coding technologies than traditional multi-material films. This can make testing essential to identify the right ink, settings, or an alternative coding solution.

My advice to brands is simple: involve your marking and coding partners as early as possible when making material changes. By doing so, you can identify and address potential challenges upfront, helping to ensure a smoother transition and avoiding costly delays.

Final reflections

As I left SPC Impact, I felt energized by the industry’s collective commitment to sustainability. The event reaffirmed that sustainable packaging isn’t just a goal—it’s a continuous journey that requires collaboration, innovation, and persistence.

Whether it’s navigating the complexities of EPR, embracing climate innovation, or rethinking traditional approaches to packaging, the time to act is now. Solitaire Townsend’s reminder of the tipping point stuck with me: momentum is building, and there’s no stopping it.

For me, SPC Impact was more than just an event—it was a powerful reminder of why we do what we do. Together, as an industry, we’re harmonizing action to create a more sustainable future.

Melissa Bosnyak is a leading advocate in the sustainable packaging community. In her role at Videojet, she oversees programs dedicated to providing Sustainable Packaging Solutions for the company’s customers. With a keen eye on the evolving landscape of sustainability and a commitment to innovation, Melissa works to help ensure that Videojet offerings not only support customers’ compliance with current regulations but are also paving the way for alignment with future standards. Her expertise and proactive approach help empower Videojet customers to meet their environmental goals effectively.