The Comprehensive Guide to Choosing a Laser Marking System

A Comprehensive Guide for OEMs and Manufacturers

Max Owen

Videojet Product Manager, Laser

Laser marking systems, Selecting a laser, Laser integration

Introduction

Modern manufacturing operations demand precision, efficiency, and permanent traceability in product coding. Laser marking has emerged as the gold standard for achieving these goals, offering high-speed, contact-free coding that produces indelible marks on products in both stationary and on-the-fly applications. This comprehensive guide will help you understand laser marking technology, evaluate different system options, and identify the key factors in selecting and implementing the right laser marking system for your needs. Whether you’re an engineer focused on technical specs or planning line integration, or a manager assessing ROI, this guide provides insights gained from tens of thousands of successful laser implementations.

Understanding Laser Marking Technology

What is laser marking?

Laser marking is a non-contact printing process that uses a focused beam of light to create permanent codes, text, or graphics on a material’s surface. Unlike ink-based printing, which deposits pigments or dyes, a laser interacts directly with the material—usually by heating or altering the surface—to produce a lasting mark without any consumables. The laser beam’s energy causes localized changes: for example, heating can remove material (ablation) or induce color changes via chemical reaction in the substrate. The result is a precise, durable mark that resists wear, solvents, and environmental conditions, making laser marking ideal for traceability and compliance codes that must remain legible throughout a product’s life.

How does laser marking work?

In simple terms, a controller directs the laser beam via mirrors driven by galvo motors to “mark” the target surface. When the concentrated light hits the material, the material absorbs the laser’s energy, converting light to heat. Depending on the material and laser settings, this can have a few different effects:

Engraving/Ablation

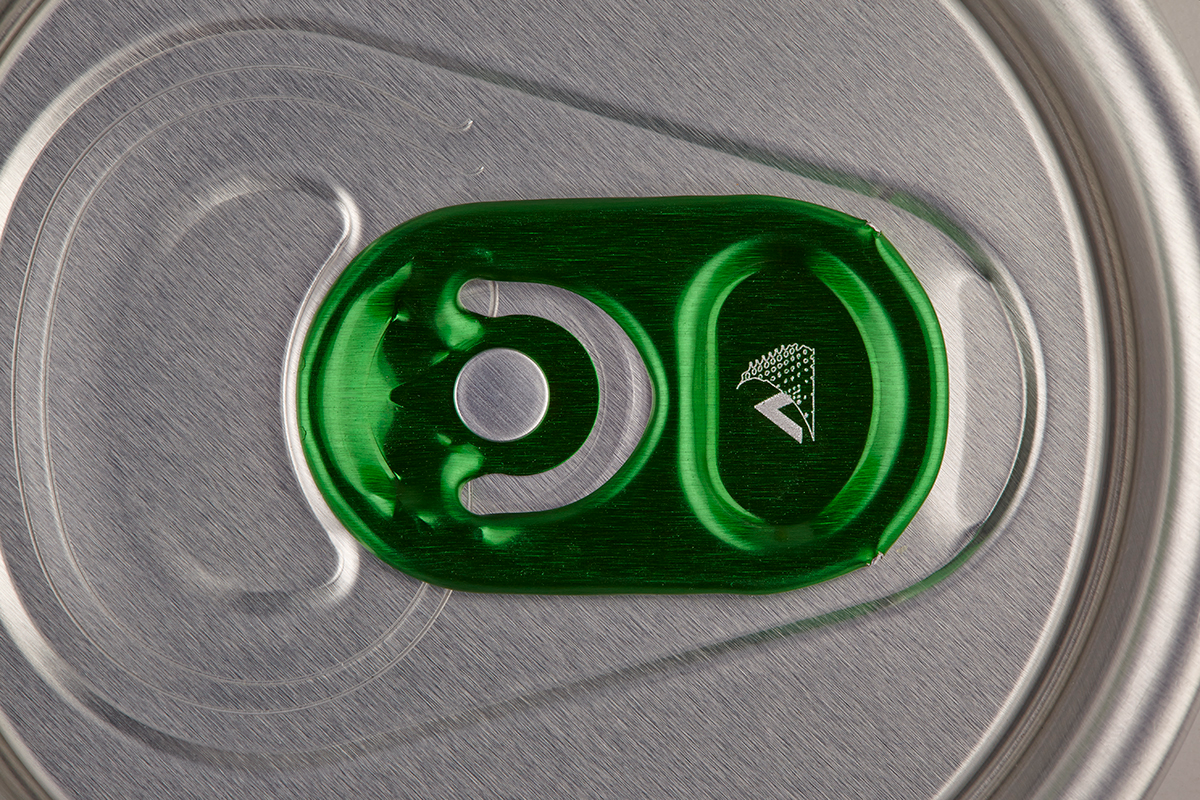

The laser removes the top layer of color from the packaging material, exposing the layer beneath to create contrast. This process produces a very shallow but permanent mark that offers excellent durability.

Etching

A milder form of engraving that removes only a small amount of material, producing a shallow mark. Etching creates marks with minimal surface disruption while still being readable.

Annealing

Instead of removing material, the laser heats the metal below its surface, causing an oxidation layer that changes color (often black). Annealing is used on steels and titanium to get a high-contrast mark without altering the surface texture.

Melting/Foaming

For certain plastics, the laser heats the material just enough to cause it to expand or foam slightly, creating a raised, lighter-colored mark. This process does not remove material and is gentle enough to preserve the structural integrity of the plastic—meaning even pressurized containers like PET bottles remain strong and safe after marking.

Staining/Color Change

In some materials, the laser’s energy triggers a chemical reaction or carbonization that visibly changes the material’s color without significant material removal.

Carbonization

For wood and other organic materials, the laser causes controlled burning or carbonization of the surface. This darkens the material to create a high-contrast, permanent mark without removing significant depth—ideal for decorative or branding applications on natural substrates.

Each of these laser marking processes has specific use cases. For example, engraving is preferred when maximum permanence is needed (e.g., VIN codes on auto parts), whereas annealing is used when surface smoothness must be preserved (e.g., medical implants). The key takeaway is that laser marking offers versatile methods to achieve a mark, and the optimal method depends on the material and application requirements.

Types of Laser Marking Systems

Not all lasers are the same. Industrial laser marking systems typically fall into a few main types, distinguished by their wavelength and technology. The laser’s wavelength determines which materials it can mark effectively because different materials absorb light energy differently. Here are the most common laser types and their characteristics:

| Laser Type | Wavelength | Ideal For | Key Traits |

|---|---|---|---|

| Fiber Laser (Ytterbium-doped fiber) | ~1,064 nm (infrared) | Metals (steel, aluminum, brass, titanium) and some high-density plastics (like ABS, polycarbonate) | High power density for etching/engraving metals with precision. Typically compact, with low maintenance and long life (up to ~100k hours). Fiber lasers can even produce marks like annealing colors on stainless steel that other lasers cannot. |

| CO₂ Laser (Carbon Dioxide gas) | ~9,300, 10,200, and 10,600 nm (far infrared) | Organic materials: paper, cardboard, glass, wood, leather, and many plastics (e.g. PVC, PET) | Excellent for high-speed marking on non-metals and transparent plastics and glass. CO₂ lasers produce marks by ablating or foaming surfaces (essentially burning the material). In general, marking metal with CO₂ requires applying an absorbing or coating paste to the metal. |

| UV Laser (Ultraviolet, often nm) | 355 nm (ultraviolet) | Heat-sensitive and broad-range materials: fragile plastics (like thin flexible film, medical-grade plastics, PVC), glass, ceramics, and even certain metals | UV lasers are sometimes called “cold marking” systems because their short wavelength is absorbed with minimal heat depth. They can mark almost any substrate with very fine detail while causing very little thermal damage. UV is ideal for applications requiring precision and material integrity (e.g. flexible film with barrier functionality for food, electronics, pharmaceuticals). |

Each laser type’s interaction with materials is unique, so choosing the right type is crucial. For instance, if you primarily mark metals, a fiber laser is usually the top choice due to its efficiency on metallic surfaces. If you need to mark packaging film or glass, a CO₂ or UV laser might be more appropriate (CO₂ for organic packaging, UV if you require very fine codes or need to minimize heat impact to ensure the barrier properties of a packaging film are not destroyed). UV lasers offer the broadest material compatibility because of their specific wavelength, often marking things that fiber or CO₂ cannot. Always confirm material compatibility with your supplier – in fact, conducting sample tests in a lab is recommended. Videojet offers sample testing in application labs worldwide to help ensure the laser type and settings produce the desired mark on your exact material.

Sample Lab

Ensure a proper code with a free sample test using your product or package.

Contact Us:

Key Factors in Selecting a Laser System

Choosing a laser marking system isn’t just about the laser itself. It’s about finding a solution that fits your production environment, marking requirements, and business goals. Below, we break down the critical selection factors:

Performance Specifications and Material Suitability

Material Tests

It all starts with the material. A laser that performs well on one type of substrate might have little to no effect on another. That’s why it’s essential to test your actual product with the laser system before making a final decision. Sample marking helps confirm whether the laser type, power, and lens configuration are right for your needs.

While marking quality is critical, it’s just as important to ensure the packaging remains intact and functional. Many suppliers offer sample marking services. Videojet, for example, can test your exact material using fiber, CO₂, and UV lasers in their applications lab to identify and recommend the best solution. This step not only helps you avoid costly mistakes but also gives you confidence in the mark quality with real, tangible results.

Laser Power

Power output (measured in watts) is a primary spec that influences marking capability. Higher power lasers can mark faster and/or deeper, especially on hard materials. For example, marking metals typically requires a 20–50 W fiber laser for surface etching. For deeper engravings or very high-speed production lines, fiber lasers with power ratings above 50 W may be used. In contrast, CO₂ lasers—commonly used for marking packaging materials like cartons—generally range from 10 W for basic applications up to 60 W or more for high-speed applications like PET bottling. UV lasers are usually low power (2–10 W) due to their different use case type of coding effect (color change), based on the wavelength. The key is to have enough power to mark at the speed and depth you need, but not so much that it overwhelms your material or budget. Power needs also vary by material – for instance, marking a thin plastic label might require only a few watts, while engraving a steel part may need tens of watts plus slower traversing speed.

Pulse Frequency and Duration

These settings influence how laser energy is delivered. In general, lower frequency pulses carry more energy per pulse (better for deeper engraving), while higher frequencies allow smoother, continuous marking with less heat per pulse (better for plastics or high-detail marking). Most modern lasers let you adjust pulse frequency (kHz) to optimize the mark quality versus speed trade-off. If your marks require a specific appearance or minimal heat impact, ensure the laser can operate in the needed pulse settings range.

Operational Safety and Compliance Considerations

Industrial lasers are powerful devices, so safety must be a top priority. Laser systems come with a classification that indicates their hazard level:

Class 1

Safe under normal operation. The laser beam is fully enclosed or otherwise not accessible. Most integrated laser marking machines (with proper enclosures) are Class 1, meaning you can use them on the factory floor without additional laser safety measures. An example of a class 1 laser is a DVD player. The device itself is a class 1 system, but the laser inside has a higher laser class. The fact that it is properly shielded makes it a class 1 system.

Class 4

High-powered lasers can cause serious eye or skin injury upon direct or diffuse exposure. Almost all open-beam industrial lasers markers are Class 4 when the beam is exposed. This class also poses numerous possible safety risks. In practice, a standalone marking laser source is Class 4, and you need to design safety protections around it.

Making Class 4 safe

If you integrate a Class 4 laser into a production line, you should implement engineering controls to essentially convert it into a Class 1 system for operators. This entails using protective enclosures and interlocks. For instance, you might have a metal laser safety enclosure around the marking area with a door. An interlock switch can be wired such that if the enclosure door opens, the laser automatically stops firing. According to our laser safety experts, proper beam shielding and interlocks are non-negotiable for smart and safe manufacturing. They ensure that no one is exposed to the beam if a cover is opened or a part is misaligned. Many modern laser systems come with built-in interlock circuits to facilitate this.

Fume Extraction

Another often overlooked safety aspect is fume management. When a laser marks a material, it can vaporize trace amounts of that material, creating fumes or smoke. Depending on what you’re marking, these fumes might be minimally harmful (e.g., a bit of burnt wood smoke) or quite hazardous. For example, laser marking PVC plastic can release chlorine gas which is toxic. It’s crucial to have a properly qualified fume extraction or ventilation system in place to remove combustion byproducts from the operator area and product surface. A good extraction system will protect workers and prevent smoke from depositing on lenses or products. Always assess the materials you’ll mark and ensure compliance with any workplace exposure limits.

Standards and Training

Adhere to laser safety standards such as ANSI Z136.1 (for safe use of lasers) and any applicable local regulations. This includes providing laser safety goggles appropriate for your laser’s wavelength to any personnel who might be exposed to an open beam (for Class 4 scenarios). Designate a Laser Safety Officer if required in your jurisdiction and conduct training so that operators understand the hazards and safety features. Fortunately, with a proper Class 1 enclosure + interlock setup, routine operation requires no special protective gear – the hazard is contained. But maintenance personnel will need to be trained on proper procedures for when the enclosure is opened for service.

Industry Regulatory Requirements (Marking Compliance)

Certain industries have specific coding requirements that can influence your choice of marking system. Laser marking excels at meeting many of these compliance needs thanks to the permanence and precision of the marks.

Unique Device Identification (UDI) for Medical Devices

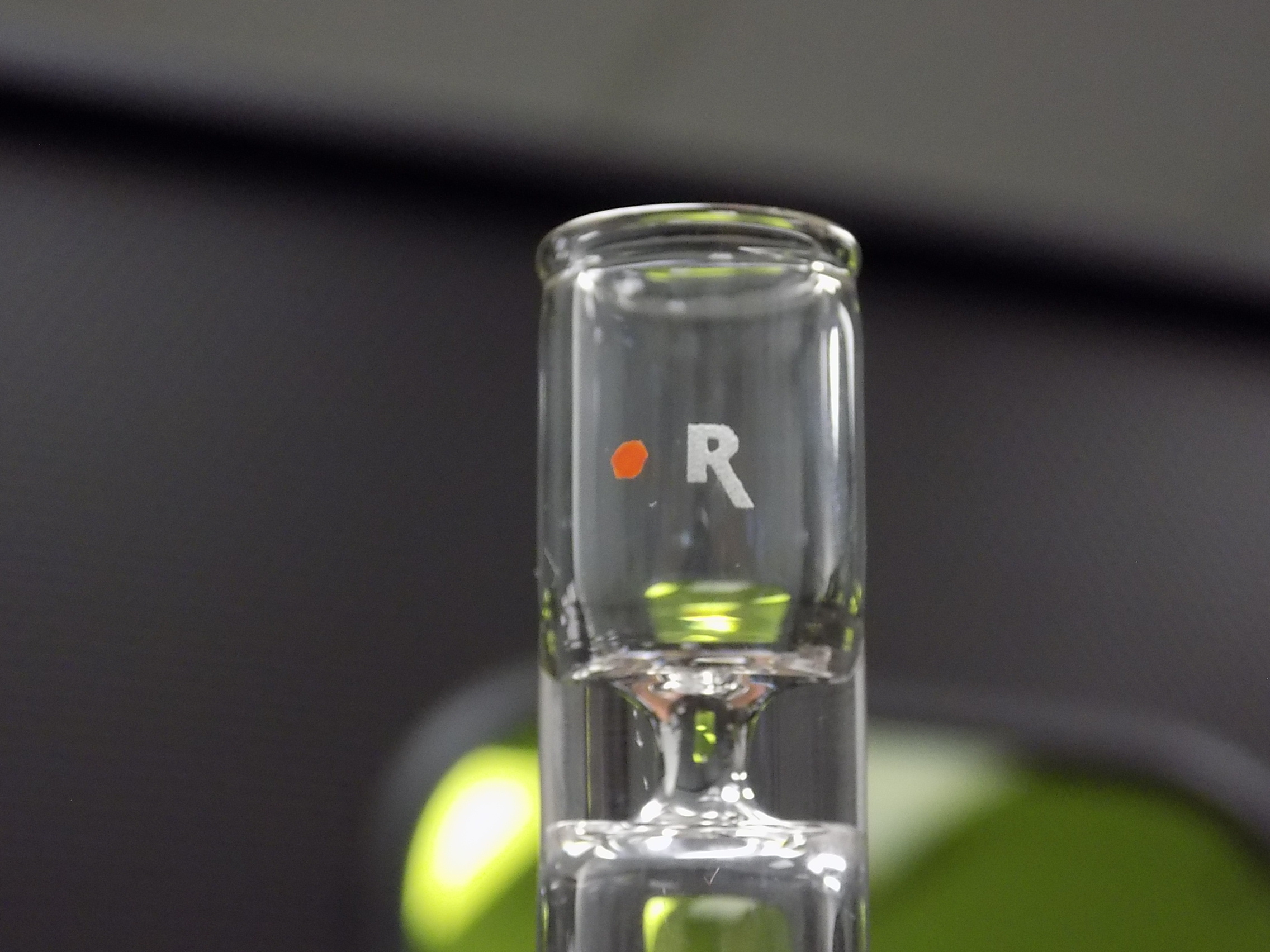

The medical industry (FDA in the U.S.) requires permanent, machine-readable codes on many instruments and implants. Lasers are often the only viable method to put a UDI code (i.e., DataMatrix) on a surgical tool or implant because it must remain intact through sterilization and years of use. If you’re in medical manufacturing, ensure the laser can produce the required mark without compromising material biocompatibility (e.g., using annealing on stainless steel tools to avoid surface roughening).

Pharmaceutical and Food Codes

High-volume industries like pharma and beverage are increasingly using lasers to apply lot codes, expiration dates, and 2D barcodes on products and packaging. Regulations here demand that codes be legible and permanent. Lasers can meet these needs (e.g., marking barcodes on foil blister packs or engraving codes on glass vials) reliably. In fact, some countries mandate engraved or embossed codes for certain products to combat counterfeiting and ensure that the code can survive challenging or complex supply chains.

Electronics and Automotive Traceability

Electronics manufacturers often need tiny codes on components (for traceability or anti-counterfeit measures). Laser marking is common for PCB coding, chip marking, and automotive parts serialization. If compliance standards (like automotive industry IAQG standards for mark quality) apply, you may also need a verification system to grade the marks. Laser marking can produce very high-grade DataMatrix codes when calibrated correctly.

Equipment Certification

On the machine side, verify that the laser system itself has required certifications (like CE marking for EU, or ANSI compliance, etc.). Reputable suppliers will provide documentation that the system conforms to electrical, radiological, and safety regulations. This is especially important if you plan to integrate the laser into a larger machine. You’ll want the components to be certified to help smooth the path for whole-system compliance.

In summary, consider the regulatory context of your products. Lasers are well-suited to help meet stringent coding regulations, but ensure the chosen system can produce the required code type, size, and durability. Often this means confirming that the mark contrast and permanence satisfy specific standard (for example, UDI guidelines or pharma 2D code specs).

Production Line Integration Considerations

Technical Integration Hurdles

Integrating a laser marking system into your production line involves mechanical, electrical, and software aspects. Planning for integration upfront will save headaches later.

Mechanical Integration (Mounting & Space)

Once a laser marking system is properly set up, it typically runs with minimal intervention—requiring far less ongoing maintenance than many other coding technologies. However, getting to that point can take more time and planning compared to installing a continuous inkjet (CIJ) printer. With CIJ, you can often unbox the printer, mount it, and be operational within an hour. In contrast, integrating a laser system may involve mounting hardware, setting up safety enclosures, adjusting focus, and programming the mark layout. While this “front-end” effort can be more involved, the long-term payoff is a reliable, low-maintenance solution. Choosing a supplier with strong application engineering and field support experience can make a significant difference—especially during setup. A partner with a robust service team can help streamline integration and quickly resolve any issues on site.

Integration Example

To illustrate integration planning, consider a yogurt packaging line with multiple lanes of cups being filled and sealed in parallel. Traditionally, such lines might use an inkjet printhead on each lane or a traversing inkjet to print date codes on the lids. With a laser, one galvanometer steering unit can cover multiple lanes if its marking field is large enough, potentially marking all lids across several lanes in one pass. This could reduce the number of devices from, say, six inkjet printers to one laser system. However, you’d need to ensure the laser’s marking area and speed can accommodate the width of all lanes and the line speed. In practice, some manufacturers have successfully replaced banks of CIJ printers with a single laser, greatly simplifying maintenance and consumables – but only after careful integration to accommodate the multi-lane layout. This kind of consolidation is a compelling benefit of lasers (fewer devices to maintain), but it requires that integration piece to be right (optics, mounting position, line control timing).

Cost of Ownership and ROI Considerations

Adopting a laser marking system is an investment. It’s important to look beyond the initial price tag and evaluate the total cost of ownership (TCO) and return on investment (ROI) over the system’s life.

Initial Investment

Laser systems generally come with a higher upfront investment compared to traditional inkjet printers or labeling systtems. A small CO₂ laser, for example, may be three to four times the cost of a high-end continuous inkjet (CIJ) system , while more powerful fiber lasers—especially those integrated with safety enclosures and conveyors—can represent a more significant capital expense. However, this initial cost is often offset over time by lower maintenance and consumable requirements. Installation costs (mounts, safety equipment, integration time) also add to the initial expenditure. Budgeting for these is important. However, when comparing technologies, consider what you might need in alternative systems. For example, a single laser might replace multiple inkjet units (as in the yogurt line example), or be able to produce marks that ink/label systems cannot do at all (thus enabling new capabilities, like direct part marking for compliance).

Minimal Consumable Costs

The huge advantage of laser marking is the lack of consumables. There are no inks, no solvents, or ribbons to buy. This immediately saves on purchasing, and on the overhead of managing stocks of fluids and dealing with waste disposal. For companies printing hundreds of millions of codes a year, ink costs add up significantly – lasers eliminate that ongoing cost. Maintenance savings also contribute as a well-made laser has few wear parts. For example, fiber lasers are solid-state and can often run for years with essentially no component replacements, whereas an inkjet printer might need regular filter changes and nozzle cleanings. Over, say, a 5-year period, the maintenance and consumables savings from a laser can often offset a large portion of its purchase cost.

Uptime and Productivity

Another cost factor is downtime. Every time you stop a line to change an inkjet cartridge or to service a printhead, you lose production. If your line goes down due to a printer fault, the cost can be dramatic. Studies show manufacturing downtime can cost tens of thousands of dollars per hour (we’ve seen up to $260k/hour) . Laser systems, once stabilized, tend to have high uptime because there is no ink system to clog or paper labels to jam. They either work or, in rare cases, need a quick lens cleaning or similarly minor service. This reliability means fewer interruptions to production, which translates to cost savings and improved efficiency. One of our experts noted that “the best laser is one you don’t even realize it’s there”, highlighting that a properly chosen laser will quietly do its job with minimal intervention.

Energy Consumption

Lasers do consume electricity, and high-power lasers can draw a few hundred to over a thousand watts when marking. Fiber lasers are very energy-efficient (converting a large portion of electrical power into laser light), whereas older YAG or some CO₂ lasers might be less so. Still, compared to the cost of consumables that lasers replace, the electricity cost is usually minor. For context, a 50W fiber laser might use ~500 W of power when active. If it ran 8 hours a day, that’s 4 kWh per day, which is just a few dollars on the electric bill. Ensure adequate electrical service for the laser, but don’t be too concerned – energy cost is not the major factor in ROI here.

ROI Calculation

When evaluating ROI, factor in:

Consumable savings: Calculate your annual spend on ink, solvent, labels, etc. That likely drops to near zero with a laser.

Labor and downtime savings: How often do operators tend to the current coding equipment (cleaning printheads, changing ribbons)? How many production hours are lost? Lasers reduce these tasks significantly.

Scrap reduction: Once applied, laser marks are consistent, permanent, and tamper-resistant— they cannot be removed without damaging the product surface. This permanence not only helps ensure reliable traceability and combat counterfeiting, but also supports regulatory compliance. A properly marked product will retain its code throughout the supply chain, reducing the risk of noncompliance and helping to avoid potential fines or recalls. Unlike wet ink systems, which can smudge or become illegible if not properly specified for the application, laser marking delivers crisp, high-quality codes every time. This improved code consistency reduces scrap and rework, minimizes customer complaints, and ultimately protects both your revenue and your brand reputation.

Productivity gains: Faster changeovers and fewer stops mean more throughput. Modern laser interfaces often allow quick product changeovers (load a new job file and go), sometimes faster than swapping ink types or labels. For example, Videojet laser controllers have tools to streamline job setup, reportedly reducing changeover time by up to 50% in some cases.

Longevity: A single laser system can last a long time. Fiber laser sources are known to run for up to ~100,000 hours MTBF (Mean Time Before Failure), which in a 2-shift operation could be well over 10 years of life. Even CO₂ lasers often last 50,000 hours on their RF tubes before needing a recharge/refill. In contrast, an inkjet printer might be considered old after 5-7 years of heavy use. Amortizing a laser over a decade of service makes it very cost-effective. In many cases, manufacturers see payback from laser insallations in under 2-3 years once all these savings are totaled.

Implementation Best Practices

Successfully deploying a laser marking system involves more than just the machine – it requires good project practices. Here are some best practices to help ensure smooth implementation and long-term success:

Conduct Feasibility Studies and Sample Testing

Do your homework upfront. Test your products with the laser to confirm marking quality and cycle time in advance. Evaluate any environmental needs – for insance, will high humidity or temperature in your facility affect the laser or the mark? By piloting the process on a small scale or in a lab, you can uncover and address issues before full production. Again, Videojet offers sample testing to ensure code requirements and packaging functionality are met.

Plan for Safety from the Start

Don’t treat safety enclosures or fume extractors as afterthoughts. Design or purchase proper enclosures concurrently with the laser selection so that they fit together. Ensure that all Class 4 laser beams will be appropriately contained Set up interlocks to any doors or access panels. If marking generates hazardous fumes (from plastics or painted surfaces), install a fume extraction unit in the marking area. This planning will help ensure you hit the ground running with a compliant and safe setup.

Prepare the Installation Site

Electrical – verify the power requirements (voltage, amperage) and have an outlet or drop installed by an electrician if needed. Mounting – have a stable bracket or frame ready to mount the laser; some suppliers provide mounting hardware or stands. Environment – lasers generally prefer clean, dry environments. If your factory is dusty or has temperature extremes, consider protective measures (like positive air pressure in the laser box, or cooling fans) per supplier recommendations.

Integrate with Line Controls

Work with controls engineers to install the laser into the production line. This might include mounting an encoder on the line for speed synchronization, adding a photocell sensor to detect products and trigger the laser, or connecting the laser to a PLC that oversees the line. Plan the logic: for example, what should happen if the line stops suddenly (most lasers can pause marking). As part of commissioning, do a dry run to fine-tune timings. For instance, ensure the mark placement is correct at various line speeds. Taking time here can hlp avoid quality issues later.

Train Operators and Maintenance Staff

Even though lasers need little day-to-day care, training is crucial. Your team should know how to safely operate the system, adjust basic settings, and respond to common alarms or faults. They should practice routine tasks like focusing the laser (if manual) or cleaning the lens. Also train them on the user interface – e.g., how to load new message patterns or adjust the date code format. For maintenance, identify any components that need periodic checking. Usually this might include cleaning the lens or replacing filters in a fume extractor. A short checklist (daily/weekly/monthly) helps keep the system in top form.

Leverage Supplier Support

During and after installation, don’t hesitate to use the resources of your laser partner. A good vendor will offer installation services or at least phone support, documentation (manuals, integration guides), and on-site training if needed. They can also help optimize settings for your application (power, speed, etc.). After the laser is in production, consider a service contract or at least know the process for getting technical support. Videojet, for instance, has a global service network. Such support can be invaluable if you run into an atypical issue, helping ensurieany downtime is minimized. Remember, you’re not just buying a machine – you’re ideally entering a partnership with the provider to keep your coding operations running smoothly.

By following these best practices, you set the stage for a successful laser marking implementation that meets your objectives from day one.

Conclusion and Next Steps

Laser marking systems, when chosen and implemented wisely, offer manufacturers a powerful tool to meet modern coding and traceability demands. In this guide, we covered how lasers work and the types available, the critical factors in selecting the right laser, and best practices to integrate and use these systems effectively. The key takeaway is that the best choice depends on your specific application – your materials, production process, and business priorities. By understanding those needs and the capabilities of today’s laser marking technologies, you can make an informed decision that will improve your operation for years to come.

Crucially, think long-term: the right laser marking solution can deliver sustained benefits – from cost savings (no consumables, less downtime) to quality improvements (permanent, high-resolution codes) to compliance (meeting industry regulations with ease). These benefits directly address common pain points like frequent printer maintenance, smeared codes, or expensive fluid expenditures. In an era where manufacturing efficiency and product traceability are critical to success, laser marking is often not just a upgrade, but a strategic investment in your production line’s future.

Finally, remember that you don’t have to navigate this journey alone. Selecting a laser system is a significant step, and partnering with an experienced supplier is invaluable. An ideal partner will have deep expertise in coding and marking (e.g., decades of industry experience and thousands of installations), and can guide you through material testing, integration, training, and ongoing support. Our team has helped manufacturers in diverse industries implement laser solutions tailored to their needs – from high-speed beverage lines to precision medical device marking. We’re here to share that knowledge with you.

Next steps

If you’re considering a laser marking system, we encourage you to reach out for a consultation or demo. We can evaluate your specific application, provide sample markings, and recommend the best system configuration for your unique needs. Taking the time to discuss your needs with laser specialists will ensure you get a solution that truly meets your performance and ROI goals. In the end, the right laser marking system implemented with care can increase efficiency, engage your team with improved reliability, and convert your investment into lasting value for your operation.