Integrating Coding Equipment into Vacuum Packaging Machines

A Guide for Manufacturing Excellence

Marc Discher

Global Marketing Manager OEM

Vacuum packaging machines, Integration

Introduction

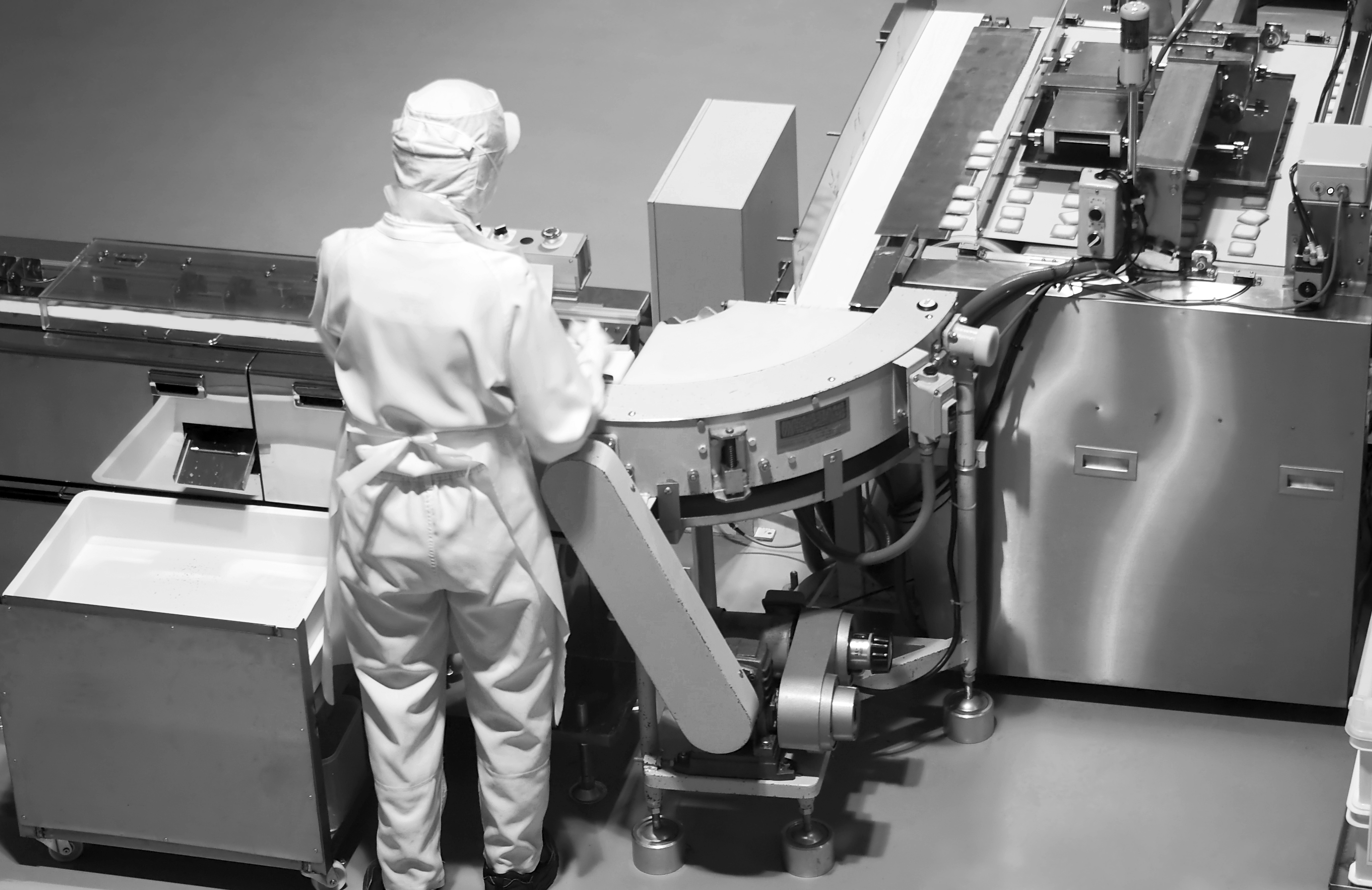

Vacuum packaging machines play a critical role in modern manufacturing, particularly within the food, pharmaceutical, and industrial sectors. These systems, including automated vacuum sealers and vacuum wrappers, are designed to extract air from packaging and form a secure seal around products, thereby extending shelf life, ensuring hygiene, and optimizing transportation and storage. As manufacturing environments evolve—driven by more stringent regulatory requirements, consumer demand for transparency, and the need for seamless supply chain coordination—the ability to mark products with accurate and traceable information has become a core component of production.

The integration of coding and labeling equipment into vacuum packaging machines ensures that essential product information—such as batch numbers, expiration dates, barcodes, and lot codes—is applied in real-time during the packaging process. This data supports traceability, regulatory compliance, inventory management, and customer confidence. For OEMs and end users alike, incorporating these systems early in the equipment design phase is a strategic decision that promotes performance, flexibility, and long-term reliability. Delaying integration or treating it as an afterthought can result in costly retrofits, sub-optimal performance, and increased risk of labeling errors or noncompliance.

Benefits of Integration

Integrating coding and labeling solutions directly into vacuum packaging —such as vacuum sealers and vacuum wrappers—offers compelling operational and business advantages. Chief among them is the ability to streamline production by automating code application, which reduces reliance on downstream labeling steps and minimizes the risk of errors. Inline integration enables packaging lines to run faster and with fewer interventions, improving overall throughput and efficiency.

In terms of traceability, integrated coding systems ensure every package is marked with precise, time-stamped information that supports real-time tracking and trace-inspection capabilities throughout the supply chain. This is especially valuable in compliance-heavy industries like food and medical devices, where accurate labeling can be the difference between regulatory approval and costly recalls.

Coding and Labeling Technologies for Vacuum Packaging

When integrating coding and labeling systems into vacuum packaging lines, selecting the right technology is critical to ensuring print quality, reliability, and compatibility with the packaging environment. Manufacturers must select the optimal technology for both primary and secondary packaging applications, considering substrate, production speed, environmental conditions, and compliance needs.

Continuous Inkjet (CIJ) Technology

CIJ is a mainstay in vacuum packaging environments due to its versatility and speed. CIJ systems apply variable data, such as batch numbers, expiration dates, and barcodes, by directing a continuous stream of ink droplets onto moving packaging materials. This contactless method is effective on a wide range of surfaces—including flexible films and even irregular or curved packages often found in vacuum sealing operations. CIJ excels at high speeds, integrates easily into existing lines, and delivers reliable codes in moist or varied environments. However, it requires regular ink and solvent maintenance, and print quality can be impacted by condensation or high-slip films.

Thermal Transfer Overprinting (TTO)

TTO offers high-resolution, durable prints on flexible film substrates. TTO uses a heated printhead to transfer ink from a ribbon onto the packaging material, producing sharp, smudge-resistant marks—ideal for barcodes, graphics, and detailed variable data. This technology is particularly well suited for vacuum sealer lines that require excellent print clarity and durability. TTO, however, is best used where film tension can be controlled since slack or wrinkled films can impact quality. Additionally, its performance can be affected by high condensation near the print area.

Laser Marking Systems

Laser coding offers permanent, high-contrast marks by using a focused beam—typically CO₂ or UV—to alter the surface of the packaging material. This ink-free method reduces consumable costs and maintenance while delivering tamper-resistant codes that withstand sterilization, moisture, oil, and solvents. These attributes make laser ideal for high-value food products and pharmaceutical applications where durability is critical.

However, when applying laser coding to vacuum packaging, it is essential to test the barrier integrity of the film or foil prior to implementation. Improper laser settings or incompatible materials can compromise the protective barrier, potentially affecting product shelf life or safety. Using a UV laser may help minimize this risk due to its lower energy absorption and more precise marking capabilities. Ultimately, the suitability of laser coding depends on the specific film or foil type and its composition, making material compatibility assessment a crucial step in the integration process.

By understanding the distinct capabilities of each coding and labeling technology and their fit for vacuum packaging equipment, OEMs and manufacturers can develop packaging lines that achieve optimal efficiency, traceability, and compliance while supporting future needs for digital integration and operational flexibility.

Integration Considerations

Effective integration of coding systems into vacuum packaging lines—whether on a standalone vacuum sealer or part of a larger automated vacuum packaging equipment solution—requires collaboration. Physical space is often limited within enclosed or compact packaging systems, making it critical to account not only for the printhead itself but also for cable routing, controller placement, access clearance, and operator ergonomics. Mounting brackets should allow for fine adjustment and quick repositioning to handle different package formats.

The harsh environmental conditions typical in many packaging facilities—especially in the food and pharmaceutical sectors—pose additional challenges. Dust, moisture, aggressive cleaning agents, and temperature fluctuations must be considered when specifying printers. Equipment with appropriate IP ratings, corrosion-resistant housings, and environmental enclosures are necessary to maintain uptime and compliance with hygiene standards. Furthermore, packaging materials such as shrink film, vacuum pouches, or laminated substrates may exhibit different surface properties that affect ink adhesion or heat transfer, demanding technology-specific tuning and testing.

Modern manufacturing lines rely heavily on interconnected systems and smart controls. Integrating coding and labeling technology into the control system of the packaging machine requires compatibility with existing communication protocols, such as Ethernet/IP, OPC-UA, Modbus, or serial interfaces. Seamless data exchange between the coder and human-machine interface (HMI) enables centralized recipe changes, code verification, and status monitoring, reducing operator burden and minimizing the risk of production errors. The coding system should also be accessible for routine maintenance and consumable replacement without requiring lengthy disassembly or interrupting production schedules—especially important in high-throughput, short-shift operations.

Integration Assessment

Get in touch with our expert sales engineers for a free integration assessment.

Contact Us

Best Practices for Successful Implementation

To maximize the value of coding and labeling integration, OEMs and manufacturers should adopt a proactive, collaborative approach beginning in the early design stages. Engaging a coding equipment supplier during the concept and prototype phases ensures that all mechanical, electrical, and software components are aligned from the start. This collaboration helps avoid costly rework and retrofitting later.

Pilot testing and line simulation are valuable tools to validate coding technology in real-world conditions. Running trial batches using actual packaging materials allows the team to fine-tune printer settings, verify code legibility, and ensure that environmental challenges are addressed before full deployment.

In addition to technical performance, the human factor is central to a successful implementation. Operators must be trained to run and maintain the coding equipment correctly, including navigation of user interfaces, adjustment of print parameters, and procedures for basic troubleshooting. Choosing a vendor that offers responsive service, spare part availability, and remote diagnostics can significantly reduce downtime and ensure long-term operational continuity.

Finally, an experienced integration partner adds tremendous value. Vendors familiar with the unique challenges of vacuum packaging lines—such as precise pouch or tray positioning, condensation issues, and film characteristics—can recommend and tailor solutions that work reliably in your environment.

Real-World Example: MULTIVAC + Videojet

A standout example of successful integration is the collaboration between us and MULTIVAC, a global leader in vacuum packaging machinery. Together, we delivered a turnkey solution for a food manufacturer that needed high-speed, hygienic packaging with traceable, compliant labeling.

The Challenge

A leading food manufacturer needed a vacuum packaging solution that could keep pace with high-volume production while ensuring every package was marked with accurate, legible variable data—such as expiration dates and lot codes. The solution had to be robust, easy to maintain, and seamlessly integrated into their existing production environment.

The Solution

Working closely with MULTIVAC, Videojet embedded our continuous inkjet and thermal transfer technologies directly into MULTIVAC’s thermoform vacuum packaging systems. This integration allowed for real-time printing of variable data directly onto packaging film—without disrupting throughput or compromising print quality.

“Things always run very, very smoothly for us with Videojet,” said MULTIVAC’s Area Sales Manager, emphasizing the ease of collaboration and system compatibility.

The Results

- The integrated system maintained high-speed production without bottlenecks, increasing the production throughput.

- Every package was printed with traceable, regulation-compliant data.

- Built-in coding eliminated the need for secondary labeling steps and minimized changeover time, reducing downtime.

- The coding equipment was designed to meet the sanitary requirements of food production environments.

Why It Matters for OEMs and Manufacturers

This case illustrates the power of early collaboration between packaging machine builders and coding technology providers. By designing integration into the machine from the outset, OEMs can offer smarter, more competitive equipment. Manufacturers benefit from a turnkey solution that supports operational excellence and brand integrity.

Integrated Coding for Vacuum Packaging

See how Videojet and MULTIVAC helped a food manufacturer boost speed, compliance, and traceability with seamless coding integration.

Conclusion

As manufacturing standards continue to rise and the need for digital traceability becomes universal, the integration of coding and labeling systems into vacuum packaging equipment—whether a compact vacuum wrapper or a high-throughput vacuum sealer line—delivers measurable benefits in quality, compliance, and productivity. From faster line speeds to improved accuracy and Industry 4.0 readiness, integrated solutions are essential for manufacturers who want to stay competitive in regulated, high-volume markets.

For OEMs and production engineers, the key to success lies in engaging coding equipment experts early in the machine development cycle. Whether you are designing a new line or upgrading existing infrastructure, early collaboration ensures that your coding solution fits seamlessly into your packaging strategy—without compromising flexibility, hygiene, or efficiency. The result is a smarter, more resilient production line that meets today’s expectations and is ready for tomorrow’s challenges.

Integrating coding into your vacuum packaging line?

Contact Us

Marc Discher is a marketing leader at Videojet Technologies with extensive experience supporting OEMs in integrating coding and marking solutions into production lines. He specializes in aligning technology with complex manufacturing needs, helping global partners improve efficiency and compliance.