Videojet Lightfoot – Compact Fiber Laser Marking System for Industrial Use

Compact Fiber Laser Marking System for High-Speed Canning Applications

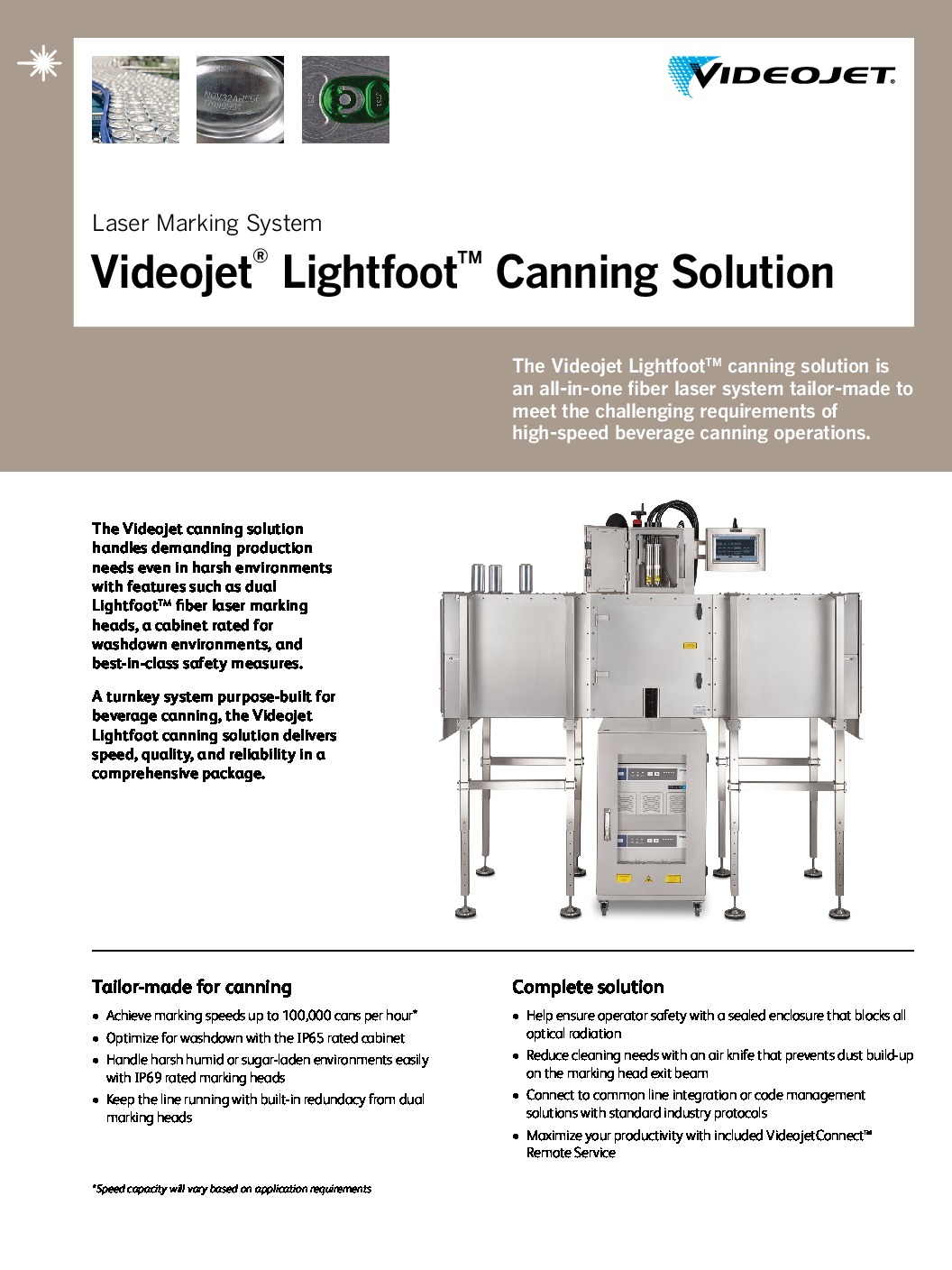

The Videojet Lightfoot™ Compact Fiber Laser Marking System is specifically developed to meet the rigorous demands of high-speed beverage canning. For manufacturers aiming to enhance their production lines, this innovative laser coding system offers a complete, integrated solution. Supported by ongoing application assistance, VideojetConnect™ Remote Service, and the industry’s largest service network, the Lightfoot™ ensures the reliability and performance needed to meet your production targets.

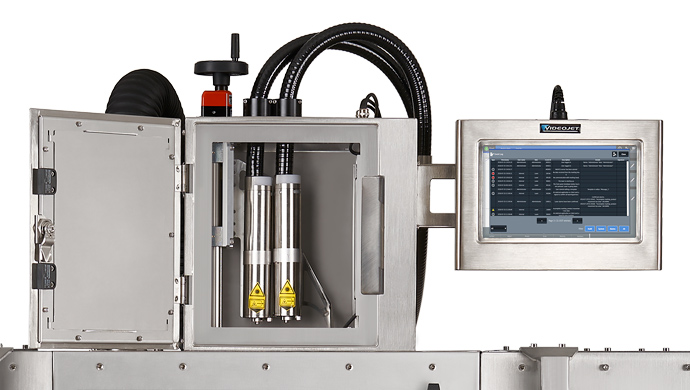

Designed to operate at ultra-fast speeds and engineered for durability in harsh environments, the Lightfoot™ Compact Fiber Laser Marking System delivers high-quality, precise laser codes in a single, all-inclusive package. Its class 1 safety design prioritizes operator safety while the dual Lightfoot™ marking heads provide built-in redundancy, ensuring maximum production uptime.

Contact us for New Equipment Sales

Specs

| Specification | Lightfoot Canning Solution |

|---|---|

| Laser System | Dual 7440 Fiber Laser |

| Laser Tube | Solid State Fiber |

| Maximum Power | 2X 30W |

| Laser Cooling | Fan |

| Maximum Line Speed | 100k cans/hour |

| Environmental Protection | IP65, IP69 (laser head) |

| Tunnel Width Options | 300mm or 600mm |

| Beam Output | Steered Beam |

| Laser Wavelength | 1.04 – 1.09 µm |

| Focal Distance Options | 112.5 mm (4.43 in) |

| Standard I/O Connectivity | Product Detect, Line Encoder, Fume Extraction |

| Optional User Interface | TCS+, CLARiTY™ Laser Controller, Smart Graph |

| Plant Air Used | No |

| Certifications/Approvals | EtherNetIP DOC, ProfiNet/PNO certificate, CE |

Benefits

Tailor-made for canning

- Achieve marking speeds up to 100,000 cans per hour*

- Optimize for washdown with the IP65 rated cabinet

- Handle harsh humid or sugar-laden environments easily with IP69 rated marking heads

- Keep the line running with built in redundacy from dual marking heads

*Speed capacity will vary based on application requirements

Complete solution

- Ensure operator safety with a sealed enclosure that blocks all optical radiation

- Reduce cleaning needs with an air knife that prevents dust build-up on the marking head exit beam

- Connect to common line integration or code management solutions with standard industry protocols

- Maximize your productivity with included VideojetConnect™ Remote Service

Applications

Documents

Video

Contact Us

Let Us Find the Right Solution for Your Business

A Coding Expert will contact you within 1 business day

Need help? We’re here for you.

New Equipment Sales & Quotes![]() : MEA.Sales@videojet.com

: MEA.Sales@videojet.com

Quick Links:

Global Offices

Sales and Distributor Search