Marc Discher

Videojet Global OEM Marketing Manager

29 July 2025

How thermal inkjet printers, thermal transfer overprinters, and UV lasers bring Tyvek® medical device packaging to life

Every second counts in healthcare and every detail matters. That’s why medical device manufacturers are under growing pressure to ensure absolute traceability of their products. With the implementation of the Unique Device Identification (UDI) systems and initiatives, medical devices must carry detailed product-specific and production-specific codes to ensure traceability from manufacturing to patient use.

For sterile packaging, DuPont™ Tyvek® has become an industry standard, due to its durability, microbial barrier properties, and tear resistance. However, printing variable data directly onto Tyvek requires specialized solutions to achieve the required high-resolution, durable codes.

Exploring Tyvek®: Reliability for medical packaging needs

Tyvek® is a porous yet resilient material made from continuous filaments of high-density polyethylene (HDPE). Its unique structure supports sterility by blocking microbial contaminants while allowing moisture vapor to escape. This breathable, lightweight material provides protection for medical devices, ranging from catheters to implantable devices, and is available in four main grades— Tyvek®1073B, 1059B, 2FS™, and 40L—to meet diverse packaging needs including tray lids and instrument packaging.

Cracking the code: The challenges of UDI marking on Tyvek®

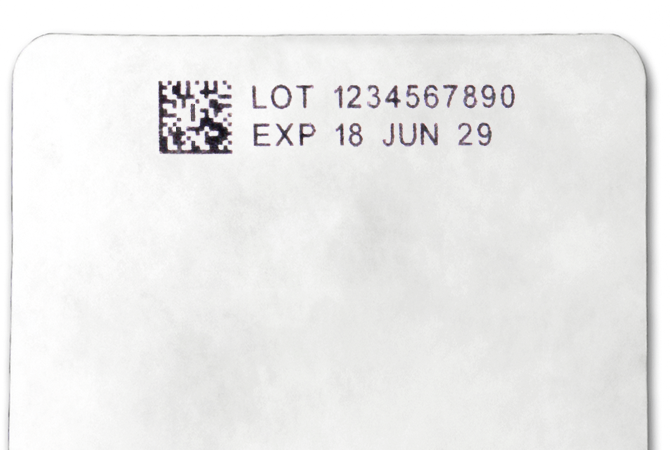

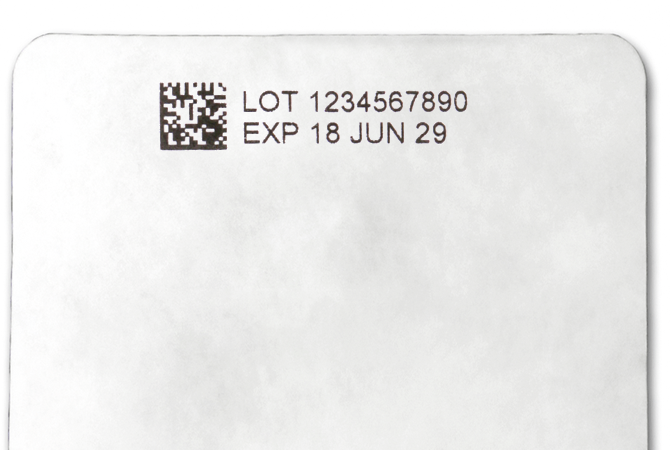

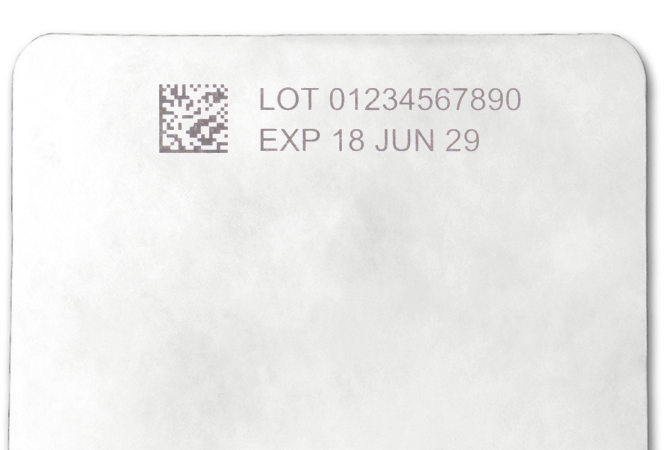

UDI compliance typically requires medical devices and packaging to include both human- and machine-readable codes, usually in the form of GS1 DataMatrix or GS1-128 barcodes. These codes must remain legible throughout the supply chain, despite the challenges of handling, sterilization, and storage. Printing directly onto Tyvek® packaging eliminates the risk of labels peeling off but introduces its own challenges due to the material’s unique surface properties. Achieving sharp, durable, and compliant codes demands the right combination of a printing or marking technology and consumables.

Three coding technologies to solve Tyvek® coding challenges

Videojet, a leader in coding and marking technologies, offers three advanced solutions for direct printing on Tyvek®:

1. Thermal inkjet (TIJ) printing: Fast, sharp, reliable

Perfect for compact production lines and high-resolution needs, TIJ uses solvent-based inks like Wolke global solvent ink to deliver:

- High-resolution printing with exceptional contrast.

- Best-in-class decap (cap open) times, ensuring smooth production runs.

TIJ printers are especially effective in tight spaces, making them perfect for integration into compact packaging lines.

2. Thermal transfer overprinting (TTO): Durable on flexible surfaces

TTO systems use a digitally controlled printhead to transfer ink from a ribbon onto flexible substrates like Tyvek®, films, and labels. For Tyvek®, Videojet recommends a rough texture black ribbon, a blend of wax and resin that helps to ensure:

- Excellent adhesion on rough and uneven surfaces.

- High-speed, sharp 2D code printing with resistance to smudging and abrasion.

- Light resistance for long-lasting readability.

3. UV laser marking: Permanent and clean

For permanent, high-contrast coding on Tyvek® 2FS™, UV laser systems generate marks through a chemical reaction that alters the material’s color without damaging it.

- Eliminates the need for consumables, like fluids and ribbon, and substrate revalidation.

- UV laser marking can meet stringent UDI requirements, achieving codes that remain intact throughout the packaging’s lifecycle.

Tested, trusted, and proven performance you can count on

The Videojet sample laboratory has conducted extensive testing to determine the ideal coding solutions for various Tyvek® types, including Tyvek® 1073B, 1059B, 2FS™, and 40L. GS1 DataMatrix ECC 200 codes were printed using TIJ, TTO, and UV laser technologies and graded using a barcode verifier in accordance with ISO/IEC 15415 standards. The tests consistently demonstrated excellent readability under laboratory conditions. With Tyvek® 40L, which features a linen-like texture, a white backing was used during verification to enhance grading quality. The overall test results showcase the reliability of Videojet technologies across Tyvek® styles.

Why does direct coding on Tyvek® beat traditional labels?

Direct printing on Tyvek® offers numerous advantages over traditional labeling methods, including:

- No risk of label detachment: Codes are printed directly onto the material, providing durability and traceability.

- Compliance with UDI standards: TIJ, TTO, and UV laser technologies can meet the strict requirements of the European Medical Device Regulation (EU MDR 2017/745), the In Vitro Diagnostic Regulation (EU IVDR 2017/746), the US FDA UDI Rule (21 CFR Part 801 & 830), andother local UDI standards when printing on Tyvek.

- Material compatibility: Videojet coding and marking technologies provide high-resolution, long-lasting codes tailored to each substrate’s unique properties.

By eliminating the risks associated with adhesive labels, direct coding helps ensure that codes remain legible throughout the packaging’s lifecycle, from manufacturing to patient use.

Why choose Videojet for Tyvek® coding?

Coding on Tyvek® isn’t one-size-fits-all. It’s a precision job that calls for the right tools, support, and expertise.

With Videojet, you get:

- Deep experience in medical device UDI compliance

- Lab-tested solutions for the Tyvek® grades that are ideal for medical device packaging

- Global support and service to keep your lines moving

From ink to laser and everything in between, Videojet helps protect what matters most: patient safety, regulatory integrity, and your reputation.

For more information about coding solutions for Tyvek® packaging, contact Videojet or visit our website.

DuPont™ and Tyvek® are trademarks or registered trademarks of affiliates of DuPont de Nemours, Inc.

Additional reading

Videojet: Pharma substrates: DuPont™ Tyvek®

Videojet: Applying variable data directly to DuPont™ Tyvek®

Videojet thermal inkjet printers

Videojet TTO printers

Videojet UV laser marking systems

European Medical Device Regulation (Regulation (EU) 2017/745 (EU MDR))

In Vitro Diagnostic Regulation (EU IVDR 2017/746)

U.S. FDI UDI Rule, Guidance, Training, and Other Resources

Stay ahead with real-time updates on the latest news: