In today’s baking industry, packaging is no longer just a functional necessity—it’s a critical component of product identity, regulatory compliance, and sustainability. With growing consumer demand for transparency and eco-friendly practices, clear date coding and sustainable packaging are essential. Whether you’re producing artisanal bread or high-volume pastries, your packaging must meet both regulatory standards and evolving sustainability trends.

Why are date and batch coding essential for baked goods?

Clear and accurate date and batch coding form the cornerstone of effective packaging. Here’s why they matter:

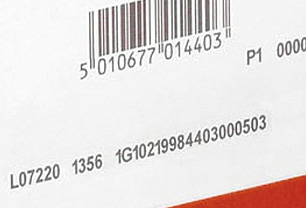

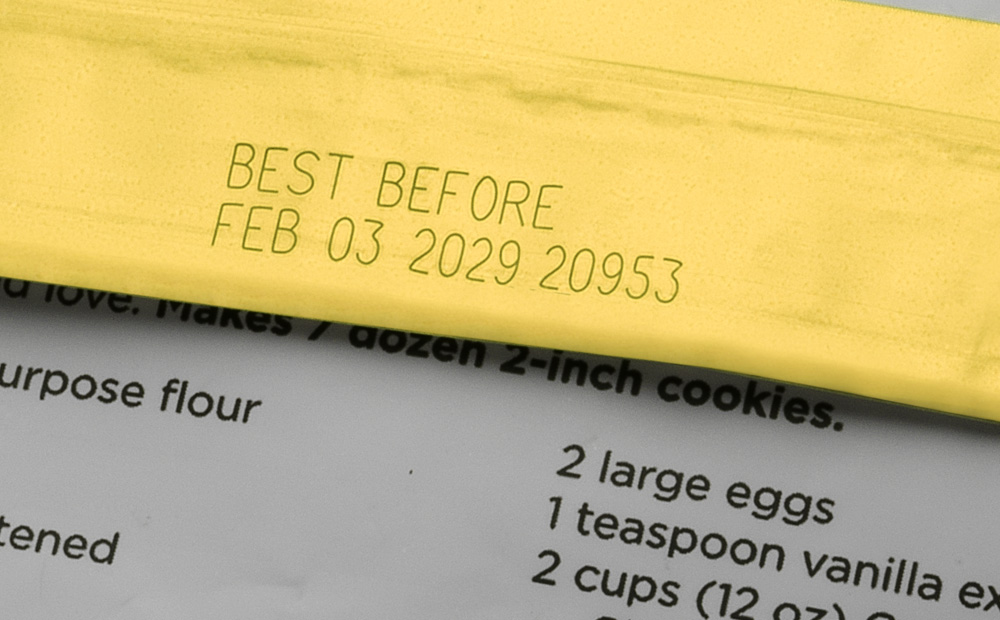

- Ensuring regulatory compliance

Most countries mandate the inclusion of best-before dates and batch or lot numbers on packaging to help ensure food safety and traceability. - Supporting traceability

In the rare event of a product recall, accurate date and batch codes allow producers to quickly isolate affected batches, minimizing impact. - Streamlining retail inventory management

Date and batch codes help retailers manage stock rotation and support optimal shelf-life control, reducing waste. - Preparing for GS1 Sunrise 2027

Upcoming barcoding standards will require more detailed product information to be encoded in a 2D format for greater transparency and traceability across the distribution chain.

Mono-materials: The future of sustainable packaging

Traditional flexible packaging often consists of multi-layer films, which are challenging to recycle due to their laminated structure. In contrast, mono-materials are engineered as single-layer plastics, designed to improve recyclability while maintaining similar performance.

Adopting mono-materials can support certain sustainability goals by offering a recyclable alternative to traditional multi-layer films. These materials can be matched with advanced coding technologies, including TIJ and UV laser marking, helping to ensure clean, high-resolution codes that meet regulatory and consumer expectations.

Learn more about mono-materials and their impact on coding and marking solutions here:

Stay ahead with real-time updates on the latest news:

Embracing sustainable packaging in the baking industry

Sustainability has become a key priority. With increasing pressure from consumers and government regulations like Extended Producer Responsibility (EPR) rules, the industry is shifting toward eco-friendly packaging materials.

Innovations in packaging materials

- Mono-material films: These recyclable films help reduce plastic waste while maintaining product protection.

- Paper-based components: Materials like paperboard cartons and boxes combine recyclability with biodegradability, providing an alternative to plastic.

However, transitioning to sustainable materials may introduce challenges in packaging operations. For instance, materials such as mono-material films or biodegradable cartons may have different porosity and surface energy, which can impact coding and marking processes. Selecting the right printing technology is crucial to addressing these challenges effectively.

Advanced printing technologies for baked goods packaging

Producing high-quality codes on sustainable packaging requires choosing the right technology. Here’s an overview of leading options:

Continuous Inkjet (CIJ)

- Ideal for high-speed production lines and uneven or curved package surfaces.

- Modern systems offer reduced fluid consumption and maintenance requirements, making them more cost-efficient per print.

- Best suited for date and batch codes; may not deliver the resolution required for 2D codes.

Thermal inkjet (TIJ)

- Delivers high-resolution (up to 600 dpi) codes on both porous and non-porous surfaces.

- Minimal maintenance requirements make it a popular choice for the baking industry.

- Advances in ink technology make it flexible enough for applications on mono-material films and paperboard packaging.

- Printheads can be combined to increase coverage for larger codes.

Laser marking

- A sustainable option that eliminates the need for consumables like ink or ribbons.

- CO2 lasers excel on labels and paperboard cartons using ablation to remove ink and reveal high-contrast marks underneath.

- UV lasers are ideal for high-contrast marks on plastics, such as mono-material films, without generating excessive heat.

- Both laser types support permanent, high-quality alphanumeric codes, linear barcodes, and 2D codes.

Thermal transfer overprinting (TTO)

- Produces high-quality text, 2D codes, and detailed product information like nutritional panels and allergen warnings.

- Works seamlessly with both intermittent and continuous motion high-speed packaging machines.

- A proven solution for flexible films and late-stage customization, making it ideal for adding variable data late in the production process. Large-format TTO printers can also accommodate additional product details, such as ingredient lists, branding elements, or regulatory information, without compromising print quality.

Choosing the ideal technology for your sustainable packaging

When selecting a coding solution for your sustainable packaging, consider the following:

- CIJ printers: Best for high-speed production with basic coding needs on a wide range of packaging materials.

- TIJ printers: Ideal for high-resolution printing on both porous and non-porous surfaces, including flexible films and paperboard.

- Laser markers: Perfect for eliminating consumables like fluids and ribbons, and for achieving permanent, high-quality marks on both paper-based packaging and plastics.

- TTO printers: Great for producing detailed information on flexible films and labels, offering versatility for late-stage customization.

Each technology has unique strengths, and the best choice depends on your production requirements, material properties, and sustainability objectives. Conducting material testing with your chosen solution is essential to ensure optimal results.

Code with confidence on baked goods packaging

As sustainability becomes a greater focus in the baking industry, selecting the right coding solution is essential. Testing your packaging materials and choosing the appropriate coding technology—such as CIJ, TIJ, laser marking, or TTO—can help you meet both regulatory requirements and consumer expectations.

By aligning your packaging and coding processes with industry demands, you can achieve compliance, maintain product quality, and support your sustainability initiatives. With careful planning and the right tools, baked goods manufacturers can balance efficiency, transparency, and responsibility in their packaging practices.

Additional resources

- Videojet: Baked Goods Coding and Labeling Solutions

- Videojet: GS1 Sunrise 2027: The Transition Period